Video

Functions:

1. UV dispensers are indeed an excellent solution for efficient, accurate and reliable bonding. UV dispensers are designed to precisely control the amount of adhesive applied, resulting in a consistent and even bond line.

2. Increase efficiency with automated features, reduce manual labor and increase production speed. These machines can quickly dispense adhesive to multiple parts, saving time and increasing overall productivity.

3. A precise control system in the UV dispenser ensures accuracy. They dispense adhesive in small quantities for precise application even in tight spaces or intricate patterns. This level of precision minimizes waste and ensures consistent bond quality.

Product Parameters:

| 1 | Model | MS-PDJ-441UV |

| 2 | Dispensing Control | Dispensing Control System |

| 3 | Dispensing Speed | According to customer's product requirements and glue types |

| 4 | Maximum Load Weight | 8kgs (for work platform) |

| 5 | Operation Range (X*Y*Z) (mm) | 400*400*100mm |

| 6 | Axis | 3 Axis (X,Y,Z) |

| 7 | Maximum Speed | X,Y 500mm/S, Z 300mm/S |

| 8 | Repeated precision | X,Y,Z ±0.02mm |

| 9 | Teaching Method | Remote Teaching/Manual Data Input/Optional: LCD Touch Screen |

| 10 | Motor system | precision stepper motor |

| 11 | Transmission mode | Precision Stepping Motor+Timing belt |

| 12 | Control Panel | Teach pendant (optional:PC or Touch Screen) |

| 13 | Voltage | AC 110V/220V,50Hz/60Hz |

| 14 | External Interface | USB + RS232 |

| 15 | Power Source | Electricity + Pneumatic |

| 16 | Air pressure requirement | 0.4 to 0.6MPa (4 to 6kg/cm2) as dry air |

| 17 | Dimension (L*W*H) (mm) | 650*630*680mm |

| 18 | Weight(kg) | 50 KG |

| 19 | Working Temperature | 10-40C° |

| 20 | Working Humidity | 20-90% RH |

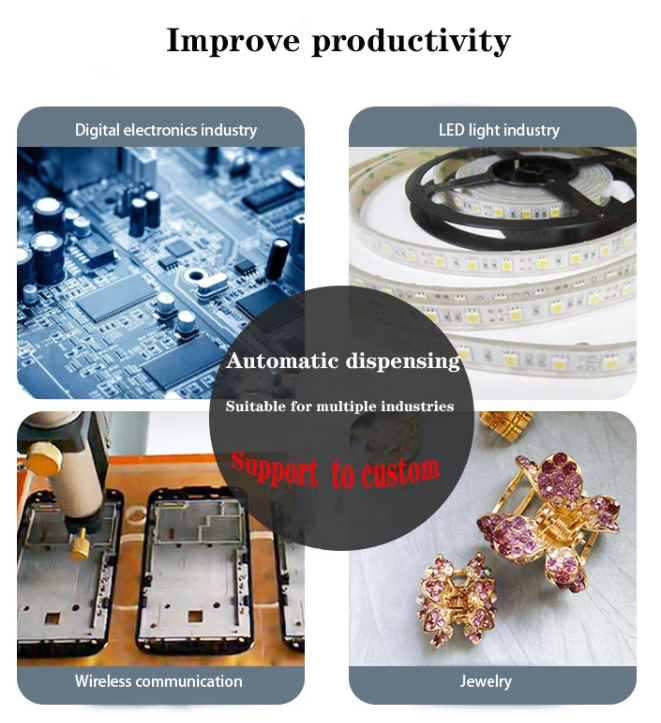

Applications:

The automatic dispensing robot is widely used in various industries,such as :

1.Electrical Products:Electronic parts,integrated circuits,circuit board solder paste,fixed and dust and moisture protection,LCD liquid crystal screen,speakers,headphone,audio,LED,optical lens,SMD transformers,relays.

2.Communication products:keypad,mobile phone casing bonding,radio,telephone,computers,MP4,electronics toys,chassis bonding,switches,connectors,plug cable.

About US

Since the establishment in 2008, Dongguan Gongming Automation Technology Co.Ltd. has devoted to standard and non-standard automation research, production,sales and provide customer service. Dedicated to provide automated management ofoverall solutions for medical, mobile, camera, motor manufacturing, small householdappliances, toys, semiconductors and other electronic digital products. Mingshuo SmartManufacturing is one of the company's brands with multiple product systems. Include3C common platform vision screw machine, special type screw, special screw and othercustomized screw locking equipment, medicalflat mask machine, disposable civilianmask machine, automatic soldering robot,ICT/FCT/ATE smart online test productionlines, semiconductor packaging equipment, magnetic winding machines as well asother non-standard automated machines.

FAQ

1.How about the package? Is it safe during the delivery?

All machine is packed by standard strong wooden carton with foam inside.

2.What is the delivery way? How many days will the machine?

We will ship the machine by DHL, Fedex, UPS, etc (Door to Door Service), around 5 days to arrive. Or by Air to your airport (Door to Airport Service), around 3 days to arrive. Or by Sea to the Seaport, Minium CBM requirement: 1 CBM, around 30days to arrive.

3.Do you provide the Warranty? How about the after sales service?

1 year warranty free for spare parts, Whole life technicial support.

We have professional after sales team, if any question, assistant videos are also provided in after-sale service.

4.Is this machine easy to use? If I have no experience, can i also operate it well?

Do you provide the user manual and operating videos to support us?

Yes, our machine is designed to use easy, Normally it will take you 2-3 hours to learn how to operate, if you are a technician, it will much faster to learn.We will provide the English user manual for free, and the operation video is available.

5.If we come to your factory, will you provide the free training?

Yes, warmly welcome you to visit our factory, we will arrange the free training for you.

6.What is the payment way?

We accept the payment terms: Bank transfer, WesterUnion, Moneygram, Paypal, etc

|

item

|

value

|

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

MINGSHUO

|

|

Condition

|

New

|

|

Weight (KG)

|

400

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Motor, Gear

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Other

|

|

Showroom Location

|

None

|

|

Type

|

Customized

|

|

Product name

|

Wire weiding machiine

|

|

Voltage

|

AC 110V/220V,50Hz/60Hz

|

|

Feature

|

High Precision

|

|

Application

|

Automation Equipment

|

| Item | Description | Content |

| 1 | Equipment Function | a. Roll wire, automatic feeding. b. Equipment automatic cutting, peeling, tinning, tin dipping, and automatic soldering(Welding of 1-4 wires is optional). c. Can achieve free switching of 4-color wires. d. Single direction welding, multi angle welding (Optional). e. After welding, the inclination angle of the wire is 0-25 °. |

| 2 | Production capacity and defects | Approximately 3000~4000 wires welded per hour. |

| 3 | PCBA board size requirements | Can be used within the range of 166-210mm. |

| 4 | Requirements for components around the solder board | a. Component height: Within the 1mm range of the solder board, no components higher than 2.6mm are allowed (Except for special circumstances). b. PCB board size: 1.5-3mm. c. PCB board position: All within the PCB range (Except for special circumstances) |

| 5 | Peeling distance | 1. Shortest peeling wire: 13mm. 2. Maximum peeling length: 170mm. 3. Peeling length: 2-4mm wire skin. |

Equipment advantages:

1. Strong universality of equipment: almost all products that meet the travel requirements for wire peeling and cutting, as well as those without dryness during welding, can be universally used.

2. The processed products have high consistency: cutting, peeling, and welding are all automatically completed by the equipment, and the length of wire and the fullness of solder joints between products will be the same.

3. Labor saving: Operator can assist in loading and unloading materials on a regular basis, with one person being able to take care of 2 to 3 equipment, without the need for skilled welding workers. Ordinary employees can watch the machine.

4. High efficiency: A medium configuration equipment with two simultaneous welding lines can weld 2100 wires per hour. High configuration equipment with four simultaneous welding lines can weld 3600 wires per hour.