Automatic soldering machine: understand the principles

Soldering is a fundamental process in electronics and manufacturing. This is the act of joining two or more metal parts together using a filler metal, called solder. While welding has traditionally been done manually, technological advancements have led to the development of automatic welding machines, which have revolutionized the welding process, making it more efficient and precise.

So, what is the principle of automatic soldering machine?

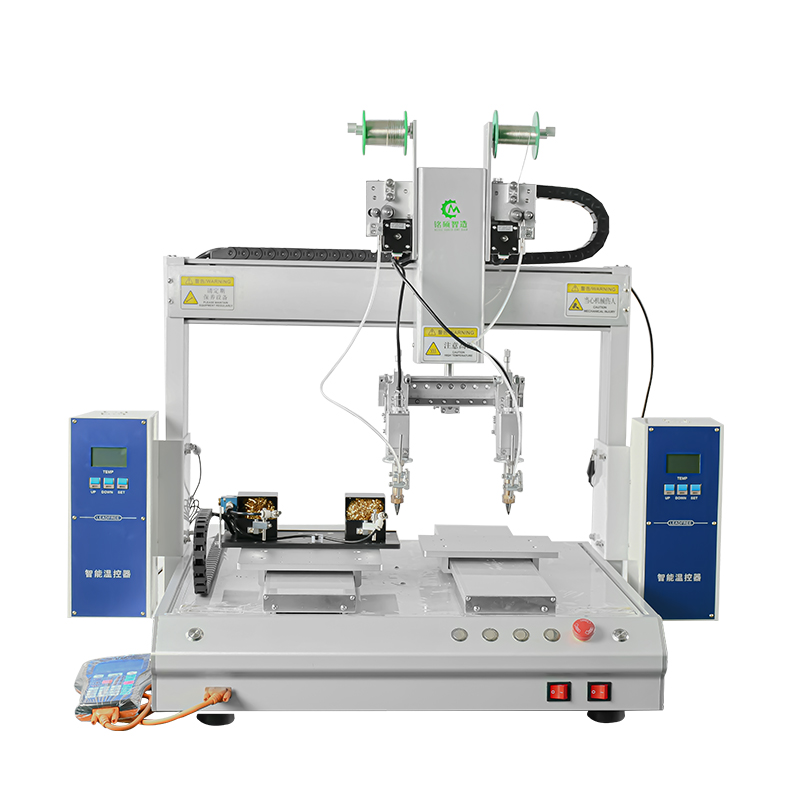

An automatic welding machine is a robotic device designed to perform welding tasks without human intervention. It combines advanced technologies such as robotics, thermal management and precise motion control to achieve accurate and consistent welding results.

The principle of automatic soldering machine revolves around three key components: soldering iron, soldering wire and control system.

The soldering iron is the part of the machine responsible for heating the solder to its melting point. It is equipped with a heating element usually made of ceramic or metal and a temperature sensor to regulate the heat. Solder wire, made of tin and lead, is fed into the soldering iron and melts, forming a bond between the metal parts being soldered.

The control system is the brain of the automatic soldering machine. It controls the entire soldering process, including regulating the temperature of the soldering iron, controlling the movement of the robotic arm, and monitoring the quality of the solder joints. The control system is programmed with precise instructions to ensure that the welding process is performed with high precision and repeatability.

The working principle of automatic welding machines is called selective welding. This means the machine is able to apply solder to specific areas of a component or printed circuit board (PCB) with high precision. It does this by combining an advanced vision system and motion control algorithms to identify solder joints and guide the soldering iron to the exact location.

In addition to selective soldering, the automatic soldering machine also integrates functions such as flux application, wire feeding, and solder joint inspection to simplify the entire soldering process. These properties further improve the quality and reliability of solder joints, making them suitable for a wide range of applications in industries such as automotive, aerospace and consumer electronics.

The principles of automatic soldering machines are based on precision, consistency and efficiency. By automating the welding process, these machines can significantly reduce human error and increase overall productivity. They are also capable of handling complex welding tasks that can be challenging for manual operators, making them an indispensable tool in modern manufacturing facilities.

The principle of automatic soldering machines revolves around the integration of advanced technologies to achieve accurate and consistent soldering results. By understanding the principles of automatic welding machines, manufacturers can fully utilize the potential of these devices to streamline production processes and provide high-quality products to customers.

Post time: Dec-28-2023