The development of technology has brought revolutionary changes to various industries, and manufacturing is no exception. One technological advancement that has had a major impact on the manufacturing process is the automatic screw machine. Also known as a screw machine or automatic screw machine, this innovative device simplifies and speeds up the process of tightening screws.

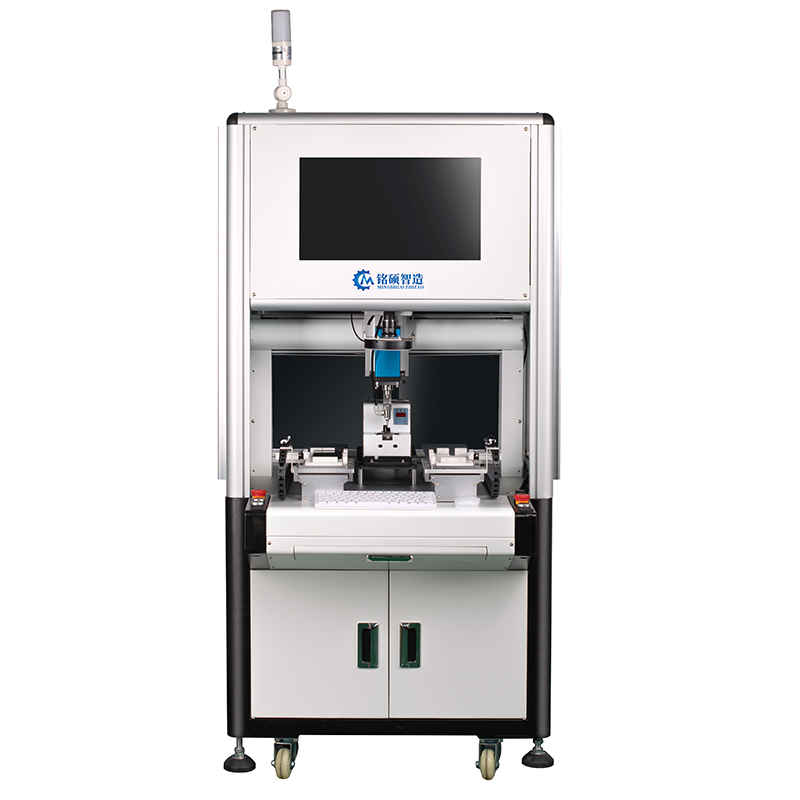

An automatic screw machine is a custom-made automatic screw machine designed to tighten screws easily and efficiently.

It comes with an electric screwdriver machine and multiple spindles, making it a multi-axis screwdriver machine. Due to their exceptional versatility and precision, automatic machines have taken center stage in manufacturing plants.

In the fast-paced world of manufacturing, time is of the essence. Traditional manual tightening methods are time-consuming and error-prone. Automatic screwdriving machines eliminate these shortcomings by providing a reliable and efficient solution. By automating the tightening process, the machine significantly reduces production times, allowing manufacturers to optimize their output and meet growing demand.

The electric screwdriver machine embedded in the automatic screw machine is the heart of the equipment. This powerful tool enables the machine to easily insert screws into a variety of materials. Its adjustable torque feature ensures the screws are securely tightened without causing damage or deformation to the workpiece. In addition, electric screwdriver machines can be programmed to adjust the rotation speed, allowing for precise control of the tightening process.

One of the distinguishing features of an automatic screw machine is its ability to handle multiple screws at the same time. The machine is equipped with multiple spindles that can accommodate different types and sizes of screws. This allows for quick and seamless transitions between different tightening operations, minimizing downtime and increasing productivity.

Additionally, automatic screw machines offer customization options to meet specific manufacturing needs. Manufacturers can program the machine to adjust various parameters such as screw size, torque and speed, ensuring each screw is tightened to the required specifications. This customizability provides unparalleled flexibility, making automatic screw machines suitable for a wide range of industries and applications.

The benefits of using an automatic screw machine go beyond efficiency and accuracy. By eliminating the need for manual tightening, the machine reduces physical stress on workers, thereby improving workplace safety and increasing employee satisfaction. Additionally, the consistency and uniformity achieved through automation improves product quality, reduces the likelihood of defects and ensures customer satisfaction.

In conclusion, automatic screw machines are a game changer in the manufacturing industry. With revolutionary features like an electric screwdriver machine and multi-axis capabilities, this custom automatic screw machine revolutionizes the fastening process. By increasing efficiency, precision and customization options, automatic screw machines have become an indispensable tool for manufacturers around the world. Investing in this cutting-edge technology not only speeds up production but also improves the overall manufacturing experience.

Post time: Nov-27-2023