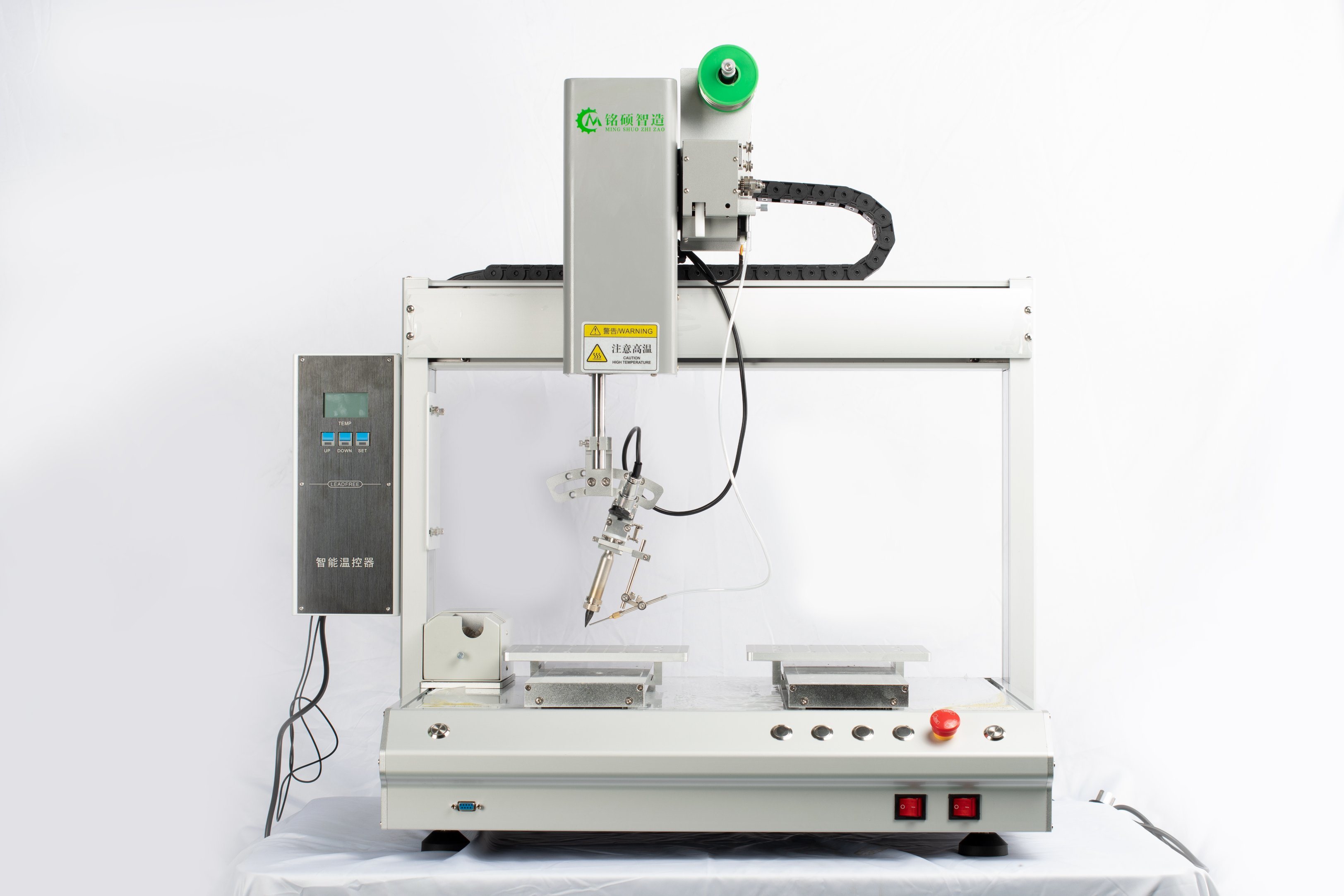

The tin pin cutting function of the automatic soldering machine is mainly used to cut off the tin pins of the components that have been soldered to facilitate subsequent sorting and installation. This function usually requires high accuracy and stability of the machine.

The following are some common ways to implement the tin-cutting function of automatic soldering machines:

- Cutting knife: The soldering machine is equipped with a special cutting knife, which is used to cut off the tin feet of the soldered components. The cutting knife is usually controlled by a mechanical arm or electric device, which can accurately cut the tin feet and maintain a certain cutting force to prevent over-cutting or cutting other parts.

- High-frequency cutting: Some advanced soldering machines use high-frequency cutting technology to cut tin feet by generating high-frequency vibrations. This method enables more precise cutting while also reducing the impact of cutting force on other parts.

- Laser cutting: Some high-end automatic soldering machines may use laser cutting technology to cut the solder feet through a laser beam. Laser cutting is highly precise and stable, allowing for very fine cuts.

No matter which method is used, the machine’s control system is usually able to automatically adjust cutting parameters based on the type and size of the component to ensure accuracy and stability of the cut. At the same time, the cut tin feet are usually collected or cleaned to facilitate subsequent processing and recycling.

It should be noted that when using an automatic soldering machine to cut tin feet, the operator should strictly follow the machine’s operating instructions and safety regulations to avoid accidents.

Post time: Sep-28-2023