In the fast-paced manufacturing industry, efficiency and precision are key factors to stay ahead of the competition. One area where these factors are critical is the welding process. Soldering is a fundamental component of electronics assembly, and the need for high-quality, reliable soldering has never been greater. This is where automatic welding machines come into play, revolutionizing the way welding is done.

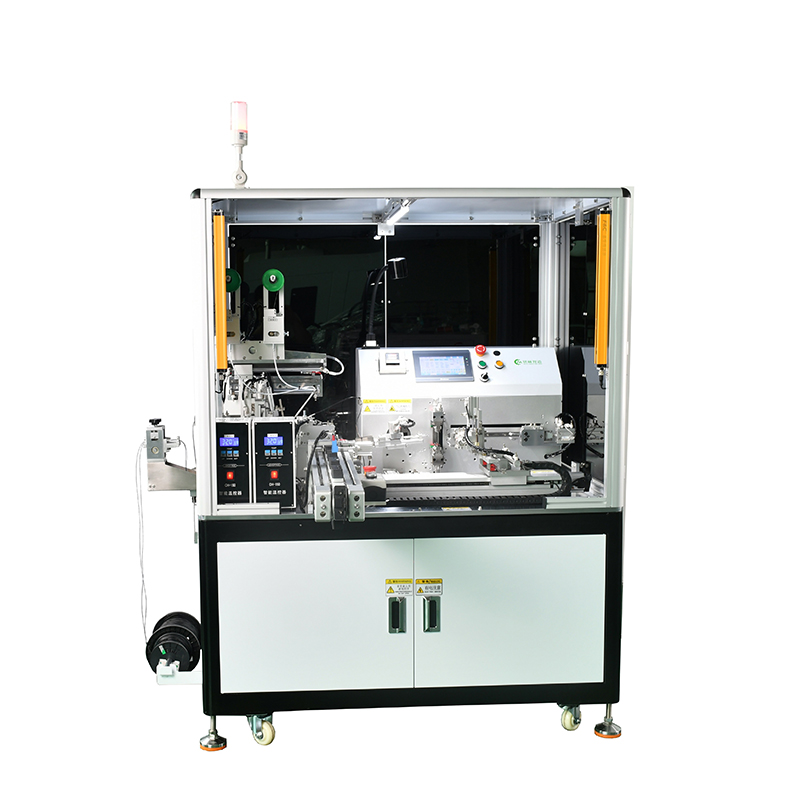

Automatic welding machines, also known as automatic welding systems, are designed to simplify the welding process, increase productivity and reduce human errors. Equipped with advanced technology, these machines are able to perform welding tasks quickly and accurately, making them essential tools for modern manufacturing facilities.

One of the main features of automatic soldering machines is their ability to handle a variety of soldering tasks, from simple wire soldering to complex circuit board assembly. This versatility makes them a valuable asset to fabricators who need to weld different types of components with varying levels of complexity.

One of the main features of automatic soldering machines is their ability to handle a variety of soldering tasks, from simple wire soldering to complex circuit board assembly. This versatility makes them a valuable asset to fabricators who need to weld different types of components with varying levels of complexity.

Through the integration of robotic arms and precision welding tools, automated welding processes are possible. These machines are programmed to follow specific welding patterns and can adjust their motion to suit different welding requirements. This level of precision ensures that every solder joint is consistent and reliable, meeting the high standards of modern electronics manufacturing.

In addition to accuracy, automatic welding machines can also save significant time. By eliminating the need for manual welding, these machines can complete welding tasks in a fraction of the time required by a human operator. This not only increases productivity but also enables manufacturers to meet tight production deadlines without compromising quality.

Additionally, automatic wire soldering machine help create a safer working environment. By reducing the need for manual soldering, these machines minimize operator exposure to harmful fumes and potential injury from hot soldering irons. This not only protects worker well-being but also ensures compliance with manufacturing safety regulations.

As technology continues to advance, the functions of automatic welding machines are also constantly evolving. Manufacturers now have access to a variety of automated welding solutions, including compact benchtop machines for low-volume production and fully integrated robotic systems for high-volume manufacturing.

Post time: Jun-29-2024