In electronics manufacturing, precision and efficiency are key factors in producing high-quality products. Soldering, in particular, plays a vital role in ensuring the reliability and performance of electronic components. Traditionally, manual welding has been the preferred method of joining components, but as technology advances, the introduction of welding robots has revolutionized the welding process.

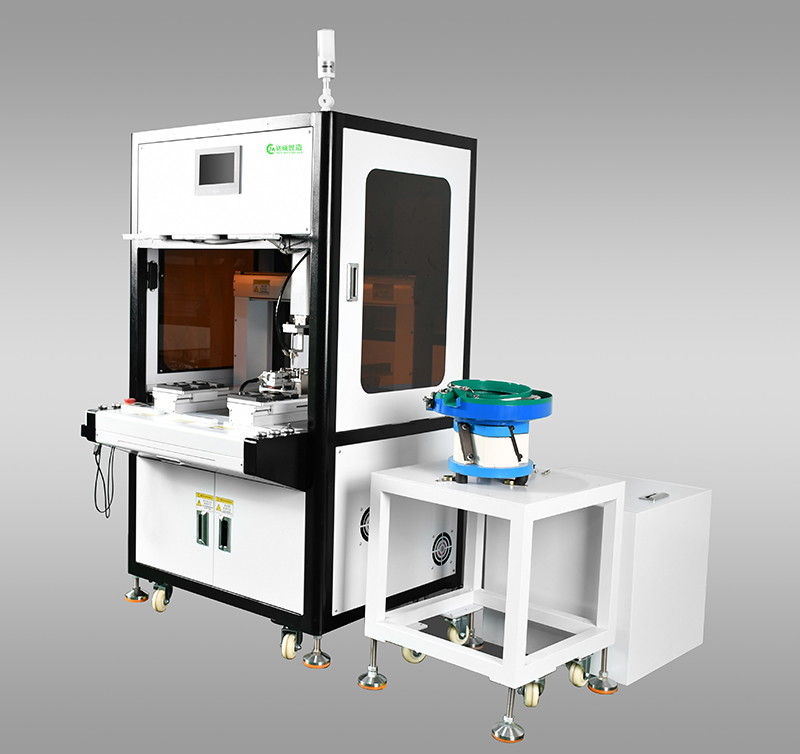

Soldering robots, also known as automatic soldering machines, are designed to provide the best solution for soldering operations of lead-free, thermally dissipated PCBs and high heat capacity components. These robotic soldering machines are suitable for a variety of difficult welding tasks and micro-welding processes, effectively improving welding quality and consistency. One of the main benefits of using a welding robot is that it can save up to 30% on solder consumption compared to manual welding, making it a cost-effective and environmentally friendly solution.

The precision and accuracy of welding robots make them ideal for handling complex welding tasks that would be challenging for human operators. These machines are able to program specific welding paths and parameters to consistently deliver high-quality solder joints, reducing the risk of defects and rework. This level of precision is especially valuable when working with small components and dense PCBs, where manual soldering can result in inconsistent and unreliable connections.

In addition to improving welding quality, welding robots can significantly increase productivity. By automating the welding process, manufacturers can increase throughput and reduce production cycle times. This not only results in cost savings but also increases scalability and flexibility to meet customer needs. Able to operate continuously without fatigue, welding robots can maintain high levels of productivity and ensure consistent performance over long-term production runs.

When considering investing in a welding robot, the price of the machine is an important factor to evaluate. While the initial cost of a robotic soldering machine may be higher than traditional soldering equipment, the long-term benefits of improved quality, reduced solder consumption, and increased productivity make it a worthwhile investment for electronics manufacturers. In addition, the versatility of welding robots allows them to adapt to a wide range of welding applications, making them a valuable asset in various industries such as automotive, aerospace, consumer electronics, and medical devices.

As the demand for high-quality, reliable electronics continues to grow, the use of welding robots in manufacturing facilities will become increasingly common. Able to deliver consistent, precise and efficient welding results, these machines represent the future of welding technology. By leveraging the capabilities of welding robots, manufacturers can enhance their production processes and stay ahead of the competitive market, ultimately providing quality products to their customers.

Post time: Jul-27-2024