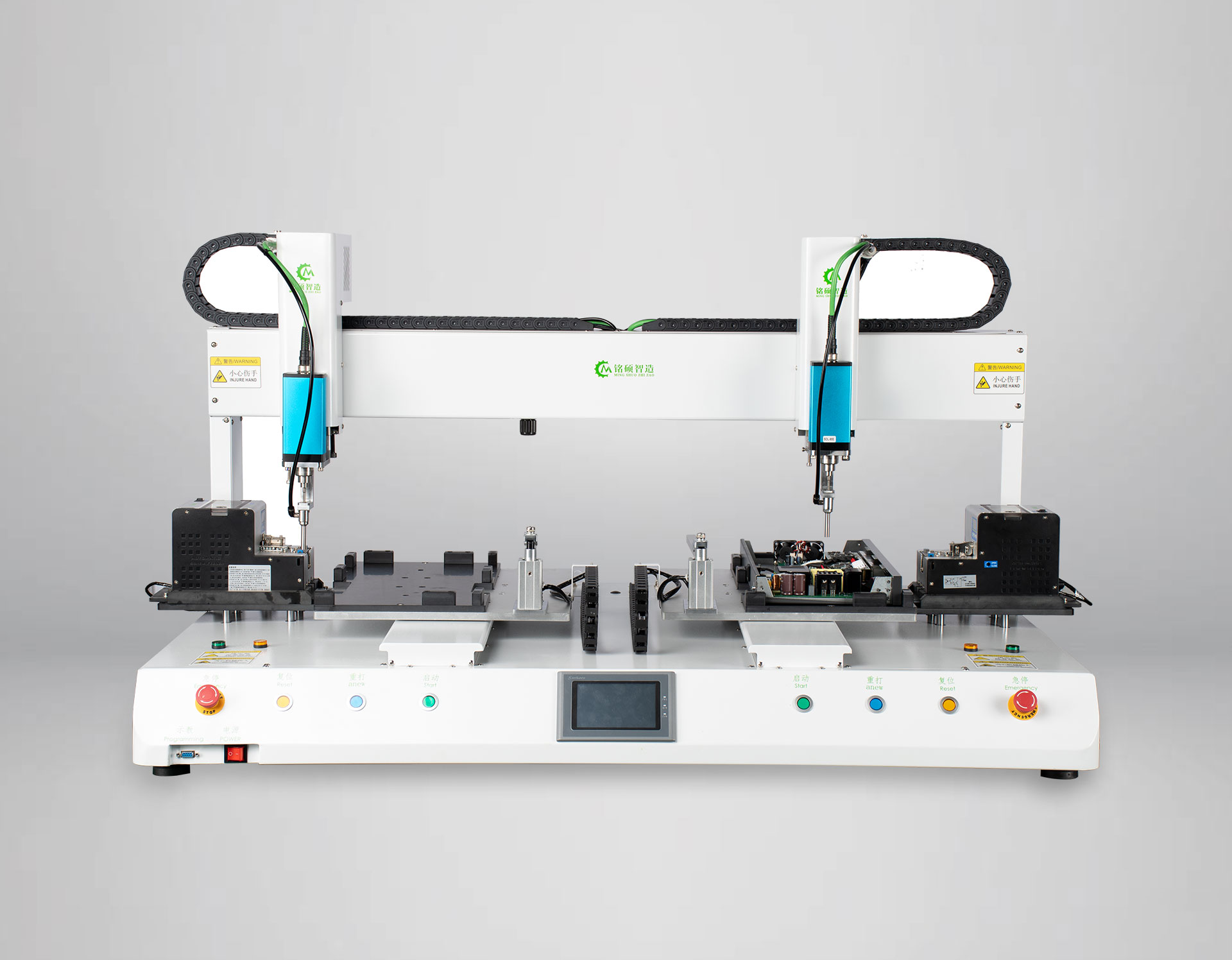

News headlines: Efficient and intelligent, helping to accelerate production – the new desktop multi-axis automatic locking screw assembly machine shockingly launched Recently, a new desktop multi-axis automatic locking screw assembly machine was officially launched, which has aroused great concern in the industry. This assembly machine adopts advanced automation technology to provide efficient and accurate screw assembly solutions for the production line, which will greatly improve production efficiency and product quality. This multi-axis automatic locking screw assembly machine has multiple robotic arms, which can assemble multiple screws at the same time, which greatly shortens the assembly time and pushes the production speed to a new height. Through the intelligent control system, the assembly machine can flexibly adjust the screw assembly sequence and speed according to the work requirements to achieve an efficient and continuous assembly process. Without manual intervention, the assembly machine can automatically complete the screw tightening work, reducing labor costs and labor intensity, while ensuring the consistency and stability of assembly quality. In addition to high efficiency, this desktop multi-axis automatic locking screw assembly machine has also made a huge breakthrough in precision. It uses a high-precision sensor and positioning system, which can detect the position and tightening force of the screw in real time, and quickly adjust the assembly pressure to ensure that each screw is correctly assembled and tightened, avoiding assembly errors and quality problems. The assembly machine also has the function of automatic adjustment of screw tightening torque, which can be flexibly adjusted according to product requirements, and is suitable for screw assembly of various specifications and materials. This desktop multi-axis automatic locking screw assembly machine also has a humanized operation interface and an intelligent control system, making the operation easier and more convenient. Through the touch screen or remote control, the operator can easily set the assembly parameters, monitor the real-time data of the assembly process and make adjustments. At the same time, the assembly machine also has an automatic fault detection and alarm system to detect and solve abnormal situations in the assembly process in time to ensure the continuous and stable operation of the production line. It is understood that the new desktop multi-axis automatic locking screw assembly machine has been used in production lines in many fields, including electronics, machinery, automobiles and other industries, and has achieved good results and reputation. Its efficient and precise assembly capabilities will bring faster production speed and higher production capacity to various industries, and help enterprises improve their efficiency and competitiveness. It is believed that the launch of this new assembly machine will bring about tremendous changes to the production line and lead the industry towards intelligence and efficiency.

Post time: Jun-29-2023