Product Features

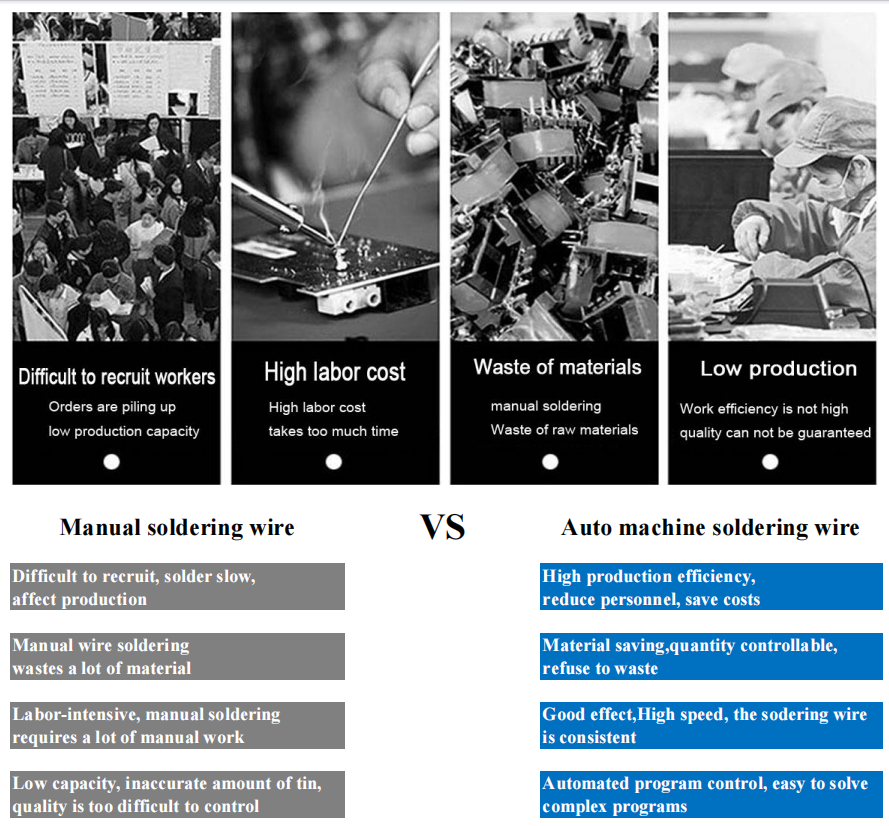

Automated welding machines are shaping the future of manufacturing by providing a combination of precision, efficiency and safety. As the demand for high-quality soldering continues to grow, these machines will play a vital role in meeting the needs of modern electronics assembly. With their ability to handle a wide range of welding tasks and their potential to save time and costs, automated welding machines will become an indispensable tool for manufacturers looking to stay competitive in the evolving manufacturing industry.

▶ The cost of one labor for 1 year = 2 automatic welding machine automatic soldering machine 1 day workload = 2-4 skilled workers

Product Parameters:

| Items | Manual soldering | Auto machine soldering |

Remarks | |

| Soldering

quality |

Tin permeability | 75% | Full penetration | |

| With tin residue | A small amount | —— | ||

| Solder quantity is inconsistent |

existence | |||

| percent of pass | About 90% | ≥95% | ||

| Consumables | High consumption of

tin and wire |

Save 15%of wire Save 25%of tin |

Relative to labor | |

| cost of investment | Multiple labor input Annual repetitive input |

One inyestment for many

years |

||

| Operator | 1 soldering station require 1 person |

e person can operate 1-4 u | No skilled workers are |

|

| labour strength | Large,unstable woker | Moderate,stable worker | ||

| Productive value |

working hours | 12H | 24H | The machine utilization rate is 98% |

| soldering efficiency | 500 solder point/H | 1500pcs wire /H | Manual soldering varies in output and quality per |

|

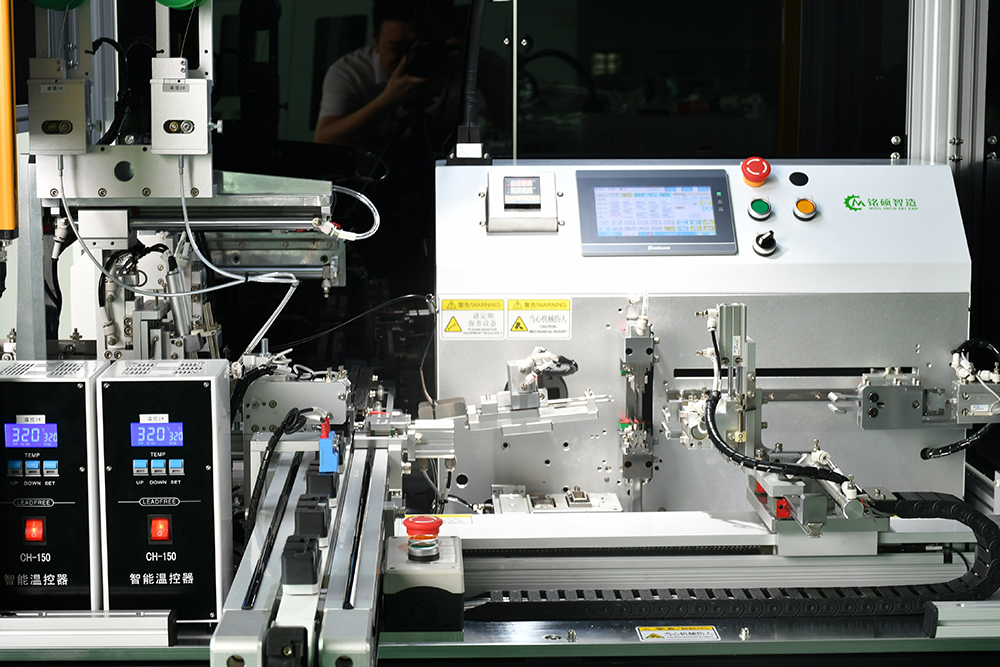

Product Details

Product Application

Why choose automatic wire sodering machine?

FAQ

1. Q: HOW IS THE AFTER SALES SERVICE?

A: We provider 1 year warranty and technical support.All machine's parts can be replaced for free within 1 year if broken(excluding error operation).

2. Q: IS IT DIFFICULT TO INSTALL TNE MACHINE?

A: The workshop should prepare a full set of facilties such as power and air compressor. For the first installation, we provide online training. For further problems, we can provide video instruction as well.

3. Q: WHAT'S THE MACHINE LEAD TIME?

A: For the standard mchines, we can delivery within 3~7days, if it is customized by customer(OEM), the lead time is 35~55 days.

4. Q:DO YOU PROVIDE CUSTOMIZED?

A: Sure, we can design the equipment accoding to tthe data of the structural section you provide. We are professional sheet metal forming machine designer and manufacturer.

5. Q: YOU ARE TRADE COMPANY OR FACTURY?

A: We are manufacturer.

6. Q:HOW TO VISIT YOUR COMPANY?

A: Our factory is located in Guangdong provice.Please advise the visiting date in advance, we can pick up you from Airport or Railway station.

|

item

|

value

|

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

MINGSHUO

|

|

Condition

|

New

|

|

Weight (KG)

|

400

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Motor, Gear

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Other

|

|

Showroom Location

|

None

|

|

Type

|

Customized

|

|

Product name

|

Wire weiding machiine

|

|

Voltage

|

AC 110V/220V,50Hz/60Hz

|

|

Feature

|

High Precision

|

|

Application

|

Automation Equipment

|

| Item | Description | Content |

| 1 | Equipment Function | a. Roll wire, automatic feeding. b. Equipment automatic cutting, peeling, tinning, tin dipping, and automatic soldering(Welding of 1-4 wires is optional). c. Can achieve free switching of 4-color wires. d. Single direction welding, multi angle welding (Optional). e. After welding, the inclination angle of the wire is 0-25 °. |

| 2 | Production capacity and defects | Approximately 3000~4000 wires welded per hour. |

| 3 | PCBA board size requirements | Can be used within the range of 166-210mm. |

| 4 | Requirements for components around the solder board | a. Component height: Within the 1mm range of the solder board, no components higher than 2.6mm are allowed (Except for special circumstances). b. PCB board size: 1.5-3mm. c. PCB board position: All within the PCB range (Except for special circumstances) |

| 5 | Peeling distance | 1. Shortest peeling wire: 13mm. 2. Maximum peeling length: 170mm. 3. Peeling length: 2-4mm wire skin. |

Equipment advantages:

1. Strong universality of equipment: almost all products that meet the travel requirements for wire peeling and cutting, as well as those without dryness during welding, can be universally used.

2. The processed products have high consistency: cutting, peeling, and welding are all automatically completed by the equipment, and the length of wire and the fullness of solder joints between products will be the same.

3. Labor saving: Operator can assist in loading and unloading materials on a regular basis, with one person being able to take care of 2 to 3 equipment, without the need for skilled welding workers. Ordinary employees can watch the machine.

4. High efficiency: A medium configuration equipment with two simultaneous welding lines can weld 2100 wires per hour. High configuration equipment with four simultaneous welding lines can weld 3600 wires per hour.