Video

Application

| Model NO. | GM-DJF-1 |

| Transport Package | Carton |

| Specification | 136x42x31mm |

| Trademark | MS |

| Origin | China |

| HS Code | 8479896900 |

| Production Capacity | 2000sets/Year |

Product Description

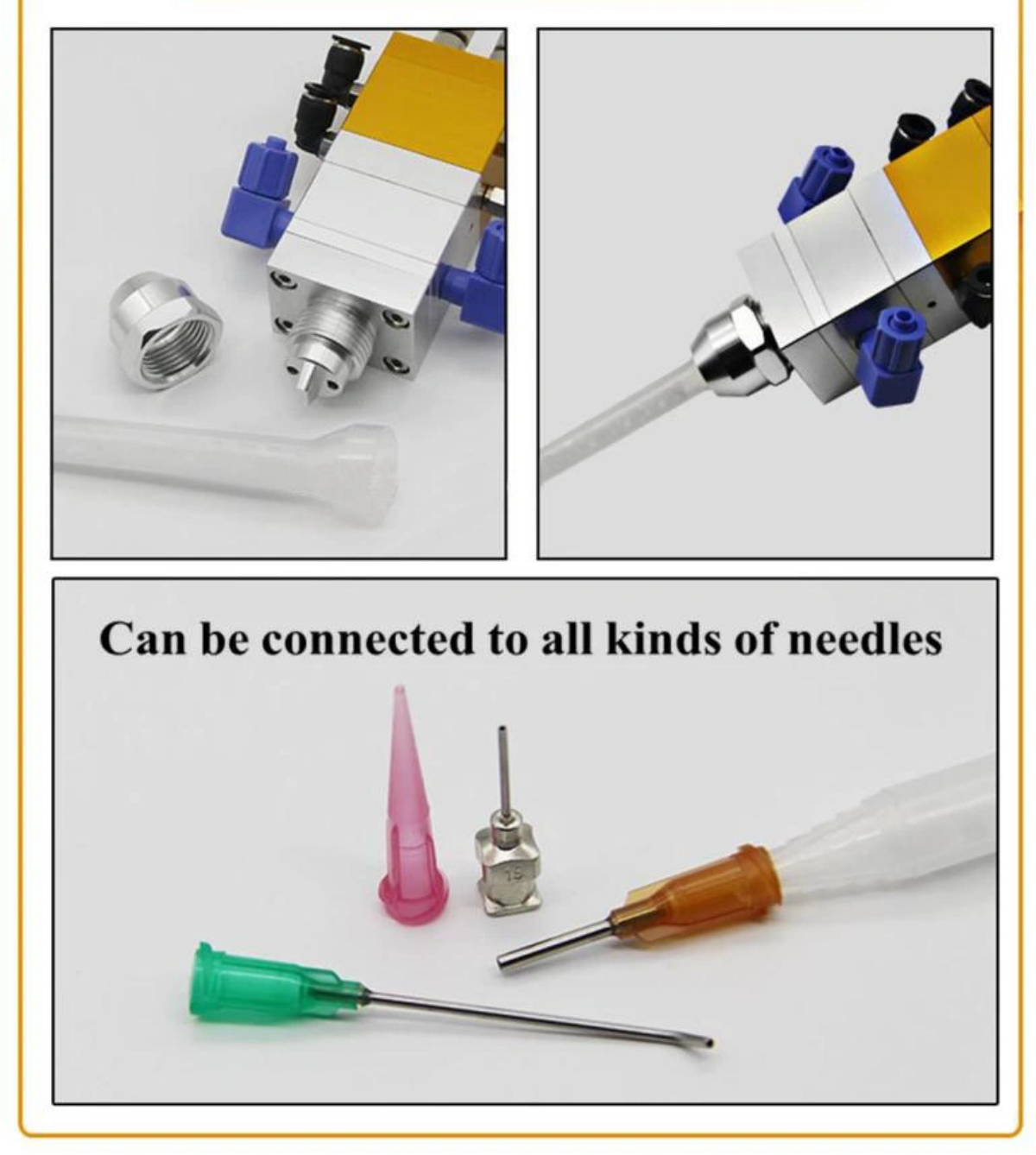

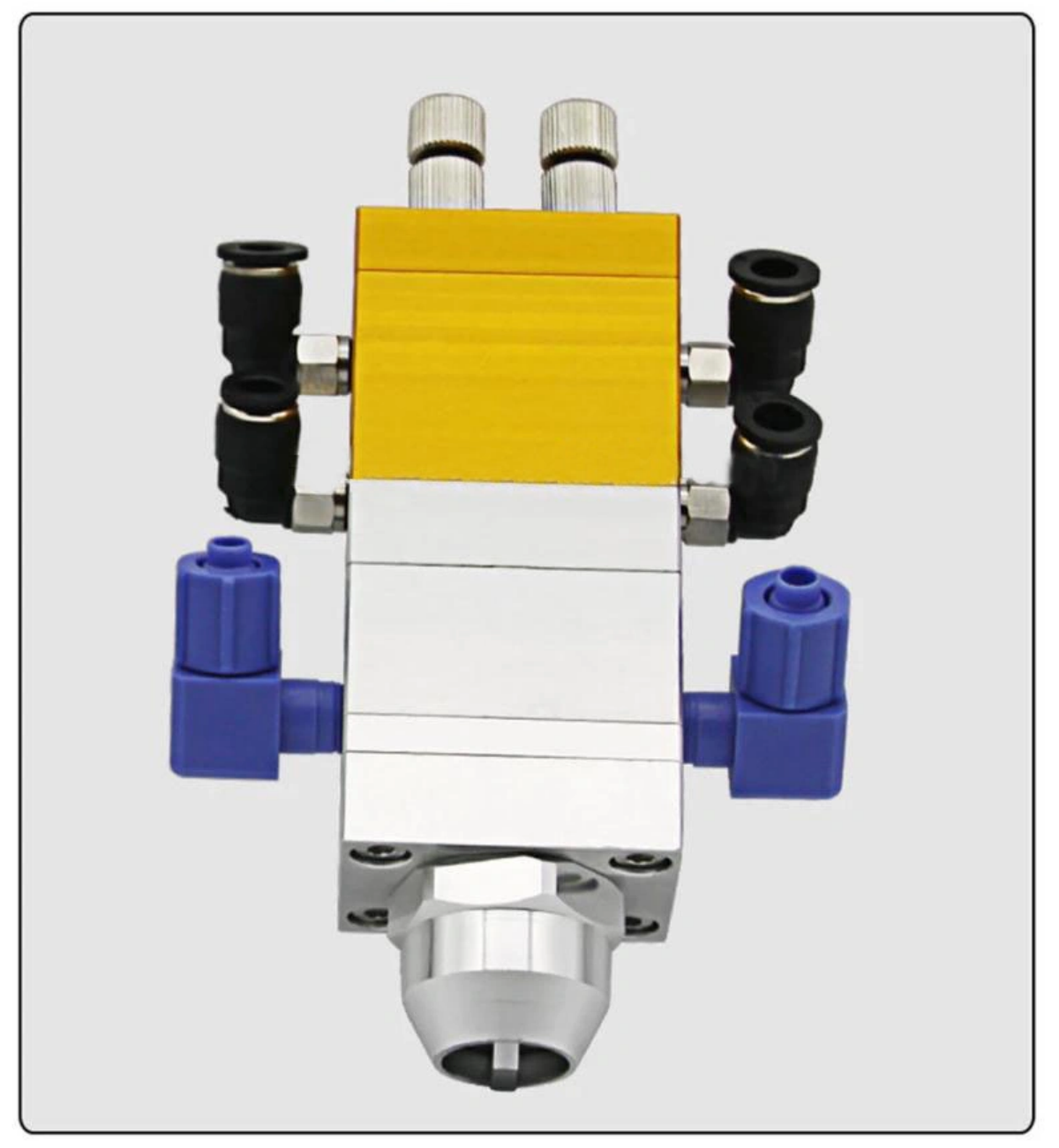

Product display

Corrosion resistant and long service life.

Accurate dispensing

Product photo

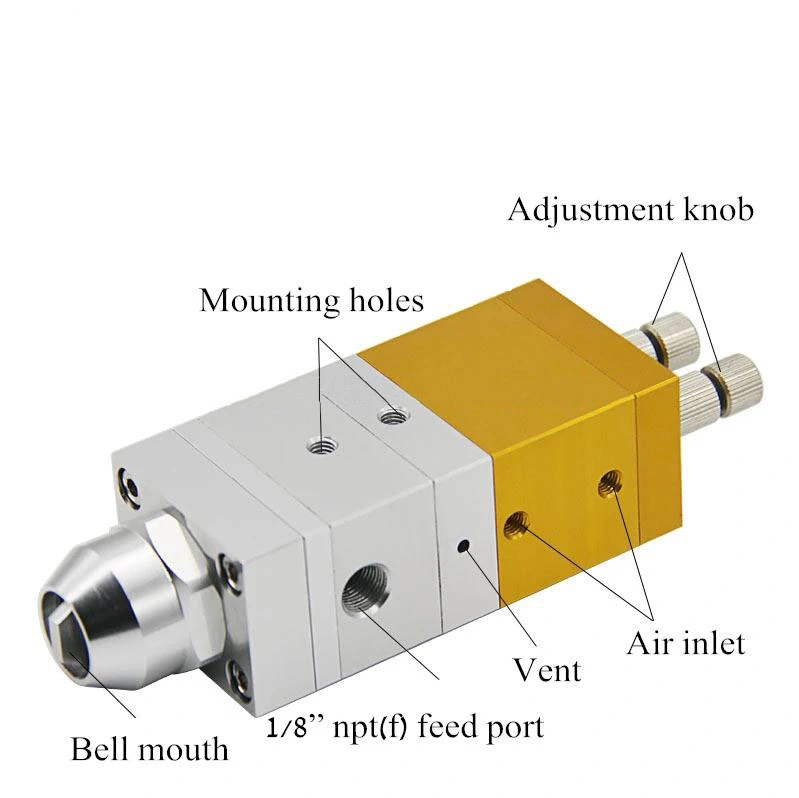

Introduction

According to the way of opening and closing, the dispensing valve is divided into: plunger type dispensing valve, thimble type dispensing valve, lift type dispensing valve, diaphragm valve, double liquid dispensing valve, Y type valve, manual Dispensing valve, spray dispensing valve, ceramic valve, jet dispensing valve

Classification

The dispensing valve is made up of four parts of the cylinder, valve body and material cylinder, and the glue assembly. The cylinder and valve body are separated by advanced sealing material to prevent glue from intruding into the cylinder. The cylinder and the cylinder are connected to the valve body of the dispensing valve to ensure concentricity with the cylinder. The pneumatic cylinder is moved by the solenoid valve to drive the center rod up and down, and the up and down movement of the center rod is used to achieve the opening and closing of the glue.

The difference

Different switching modes, the applicable fluid is different, the sucking type dispensing valve adopts the upward movement to close the rubber structure, so that the glue is stopped and the glue is broken back at the same time, and the residual glue on the remaining needle is reduced, so that the dispensing does not occur. Leakage, drawing and other phenomena. The thimble-type dispensing valve and the suction-type dispensing valve are the opposite closing structure, and the glue is fast.

Application

Widely used in electronic products, mobile phone buttons, LED lamps, LCD, electrical switches, household appliances, battery packaging, keyboard and mouse, transformers, golf balls, coils, cameras, motors, medical equipment, watches, headphones, speakers and other applications.

Product Details

|

item

|

value

|

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

MINGSHUO

|

|

Condition

|

New

|

|

Weight (KG)

|

400

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Motor, Gear

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Other

|

|

Showroom Location

|

None

|

|

Type

|

Customized

|

|

Product name

|

Wire weiding machiine

|

|

Voltage

|

AC 110V/220V,50Hz/60Hz

|

|

Feature

|

High Precision

|

|

Application

|

Automation Equipment

|

| Item | Description | Content |

| 1 | Equipment Function | a. Roll wire, automatic feeding. b. Equipment automatic cutting, peeling, tinning, tin dipping, and automatic soldering(Welding of 1-4 wires is optional). c. Can achieve free switching of 4-color wires. d. Single direction welding, multi angle welding (Optional). e. After welding, the inclination angle of the wire is 0-25 °. |

| 2 | Production capacity and defects | Approximately 3000~4000 wires welded per hour. |

| 3 | PCBA board size requirements | Can be used within the range of 166-210mm. |

| 4 | Requirements for components around the solder board | a. Component height: Within the 1mm range of the solder board, no components higher than 2.6mm are allowed (Except for special circumstances). b. PCB board size: 1.5-3mm. c. PCB board position: All within the PCB range (Except for special circumstances) |

| 5 | Peeling distance | 1. Shortest peeling wire: 13mm. 2. Maximum peeling length: 170mm. 3. Peeling length: 2-4mm wire skin. |

Equipment advantages:

1. Strong universality of equipment: almost all products that meet the travel requirements for wire peeling and cutting, as well as those without dryness during welding, can be universally used.

2. The processed products have high consistency: cutting, peeling, and welding are all automatically completed by the equipment, and the length of wire and the fullness of solder joints between products will be the same.

3. Labor saving: Operator can assist in loading and unloading materials on a regular basis, with one person being able to take care of 2 to 3 equipment, without the need for skilled welding workers. Ordinary employees can watch the machine.

4. High efficiency: A medium configuration equipment with two simultaneous welding lines can weld 2100 wires per hour. High configuration equipment with four simultaneous welding lines can weld 3600 wires per hour.