Product Features

An automated soldering robot, also known as an automatic welding system, consists of a series of equipment designed to perform welding tasks without human intervention. These machines utilize advanced technology to achieve precise and reliable welding results. One of the most common types of automatic welding machines is the wire welding machine, which is specifically designed for welding wires and cables in electronic assemblies.

Product Parameters:

Product Details

The wire bonding machine also has the characteristics of intelligence. Modern wire bonding machines are generally equipped with advanced control systems and human-machine interfaces, and the operation is simple and convenient. Through the intelligent control system, the wire bonding machine can automatically adjust the welding parameters and monitor the welding process in real time to ensure the stability and consistency of the welding quality.

The wire bonding machine also has safety features. It adopts multiple safety measures, such as protective cover, emergency stop switch, etc., which provide good safety guarantee for operators. The wire bonding machine also has functions such as overload protection and fault self-checking, which effectively prevent machine failures and operating errors. To sum up, as an important mechanical equipment, the wire bonding machine has high-efficiency welding capabilities, reliable

Product Application

The equipment has strong versatility and high scalability

About US

Since the establishment in 2008, Dongguan Gongming Automation Technology Co.Ltd. has devoted to standard and non-standard automation research, production,sales and provide customer service. Dedicated to provide automated management ofoverall solutions for medical, mobile, camera, motor manufacturing, small householdappliances, toys, semiconductors and other electronic digital products. Mingshuo SmartManufacturing is one of the company's brands with multiple product systems. Include3C common platform vision screw machine, special type screw, special screw and othercustomized screw locking equipment, medicalflat mask machine, disposable civilianmask machine, automatic soldering robot,ICT/FCT/ATE smart online test productionlines, semiconductor packaging equipment, magnetic winding machines as well asother non-standard automated machines.

FAQ

1. Q: HOW IS THE AFTER SALES SERVICE?

A: We provider 1 year warranty and technical support.All machine's parts can be replaced for free within 1 year if broken(excluding error operation).

2. Q: IS IT DIFFICULT TO INSTALL TNE MACHINE?

A: The workshop should prepare a full set of facilties such as power and air compressor. For the first installation, we provide online training. For further problems, we can provide video instruction as well.

3. Q: WHAT'S THE MACHINE LEAD TIME?

A: For the standard mchines, we can delivery within 3~7days, if it is customized by customer(OEM), the lead time is 35~55 days.

4. Q:DO YOU PROVIDE CUSTOMIZED?

A: Sure, we can design the equipment accoding to tthe data of the structural section you provide. We are professional sheet metal forming machine designer and manufacturer.

5. Q: YOU ARE TRADE COMPANY OR FACTURY?

A: We are manufacturer.

6. Q:HOW TO VISIT YOUR COMPANY?

A: Our factory is located in Guangdong provice.Please advise the visiting date in advance, we can pick up you from Airport or Railway station.

|

item

|

value

|

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

MINGSHUO

|

|

Condition

|

New

|

|

Weight (KG)

|

400

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC, Engine, Bearing, Motor, Gear

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Manufacturing Plant, Machinery Repair Shops, Other

|

|

Showroom Location

|

None

|

|

Type

|

Customized

|

|

Product name

|

Wire weiding machiine

|

|

Voltage

|

AC 110V/220V,50Hz/60Hz

|

|

Feature

|

High Precision

|

|

Application

|

Automation Equipment

|

| Item | Description | Content |

| 1 | Equipment Function | a. Roll wire, automatic feeding. b. Equipment automatic cutting, peeling, tinning, tin dipping, and automatic soldering(Welding of 1-4 wires is optional). c. Can achieve free switching of 4-color wires. d. Single direction welding, multi angle welding (Optional). e. After welding, the inclination angle of the wire is 0-25 °. |

| 2 | Production capacity and defects | Approximately 3000~4000 wires welded per hour. |

| 3 | PCBA board size requirements | Can be used within the range of 166-210mm. |

| 4 | Requirements for components around the solder board | a. Component height: Within the 1mm range of the solder board, no components higher than 2.6mm are allowed (Except for special circumstances). b. PCB board size: 1.5-3mm. c. PCB board position: All within the PCB range (Except for special circumstances) |

| 5 | Peeling distance | 1. Shortest peeling wire: 13mm. 2. Maximum peeling length: 170mm. 3. Peeling length: 2-4mm wire skin. |

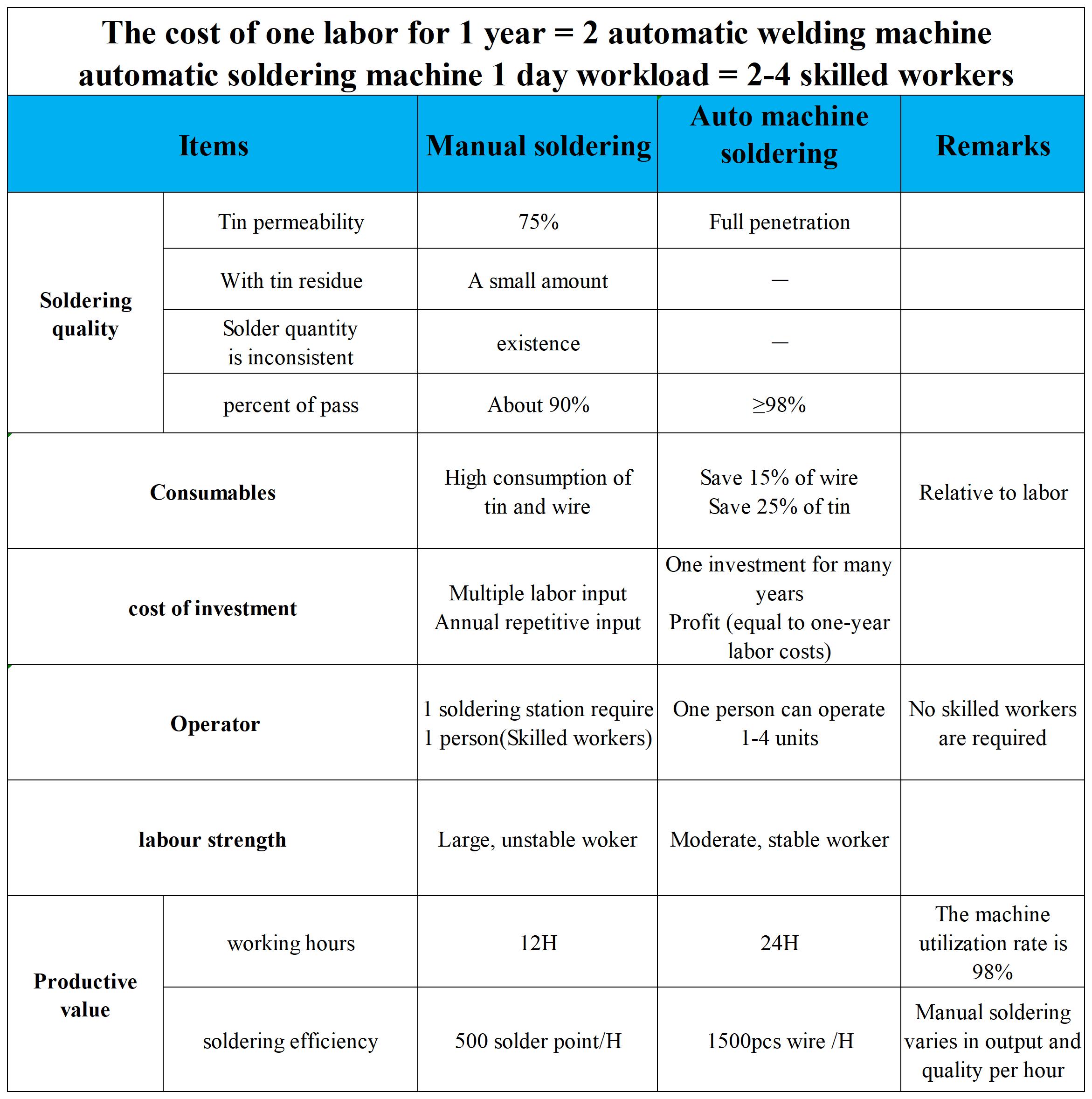

Equipment advantages:

1. Strong universality of equipment: almost all products that meet the travel requirements for wire peeling and cutting, as well as those without dryness during welding, can be universally used.

2. The processed products have high consistency: cutting, peeling, and welding are all automatically completed by the equipment, and the length of wire and the fullness of solder joints between products will be the same.

3. Labor saving: Operator can assist in loading and unloading materials on a regular basis, with one person being able to take care of 2 to 3 equipment, without the need for skilled welding workers. Ordinary employees can watch the machine.

4. High efficiency: A medium configuration equipment with two simultaneous welding lines can weld 2100 wires per hour. High configuration equipment with four simultaneous welding lines can weld 3600 wires per hour.